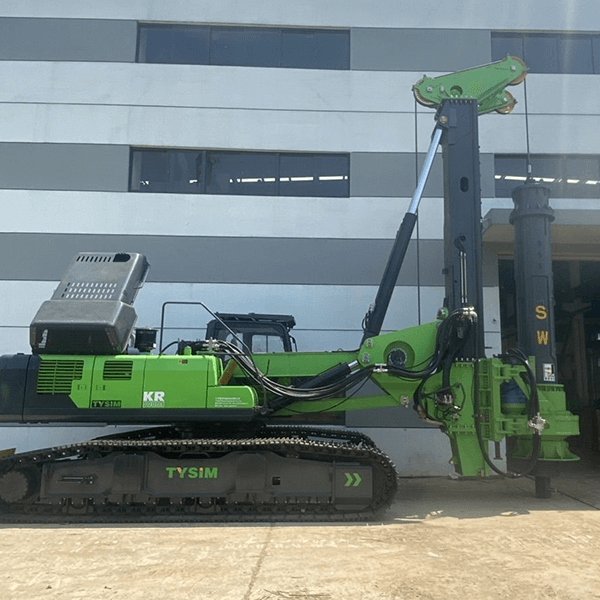

Rotary Drilling Rig KR90C

Product Introduction

KR90C rotary drilling rig is equipped with the Caterpillar CAT318D chassis of extraordinary stability and reliability. It adopts the Caterpillar CAT C4.4 electric control turbo-supercharged engine to provide strong power and conformity with EPA Tier III emission standard. KR90C rotary drilling rig is used in pile foundation for town, such as highways, railways and bridges. KR90C rotary drilling rig with max. depth 28m interlocking Kelly bar and max. diameter 1200mm.

|

Technical Specification of KR90C Rotary Drilling Rig |

|

|

Type |

KR90C |

|

Torque |

90 kN.m |

|

Max. drilling diameter |

1000 mm |

|

Max. drilling depth |

32m |

|

Speed of rotation |

8~30 rpm |

|

Max. crowd pressure |

90 kN |

|

Max. crowd pull |

120 kN |

|

Main winch line pull |

90 kN |

|

Main winch line speed |

72m/min |

|

Auxiliary winch line pull |

20 kN |

|

Auxiliary winch line speed |

40 m/min |

|

Stroke(crowd system) |

3200 mm |

|

Mast inclination(lateral) |

±3° |

|

Mast inclination(forward) |

3° |

|

Max. hydraulic pressure |

34.3 MPa |

|

Control hydraulic pressure |

3.9 MPa |

|

Travel speed |

2.8 km/h |

|

Traction force |

98 kN |

|

Operating height |

14660 mm |

|

Operating width |

2700 mm |

|

Transport height |

3355 mm |

|

Transport width |

2700 mm |

|

Transport length |

12270 mm |

|

Overall weight |

28t |

|

Chassis |

|

|

Type |

CAT 318D |

|

Engine |

CAT3054CA |

Product Advantage

1. The patented luffing mechanism in the shape of parallelogram enables operation within an extensive area. The mast of rotary drilling machine is designed in box structure of high strength and rigidity to effectively ensure the drilling accuracy. The lubrication-free bearing is used at each hinge joint to provide flexible rotation.

2. The power unit is controlled by a pressurizing or pulling hydraulic cylinder, installed with drilling hydraulic motor, spring shock absorber at the upper part and the drive head (opening the drill head) at the lower part, in addition, it’s also equipped with the driver set suitable for friction-type and internal locking type drill rods, as well as a drill rod guide frame with bearings.

3. KR90C rotary drilling rig imported CAT318D chassis with mature technology ensures stable and reliable performance.

4. The innovative design concept of transporting the hydraulic rotary drilling rig in one integrated structure offers great efficiency (cost saving) when transferring between the transporting status and construction status.

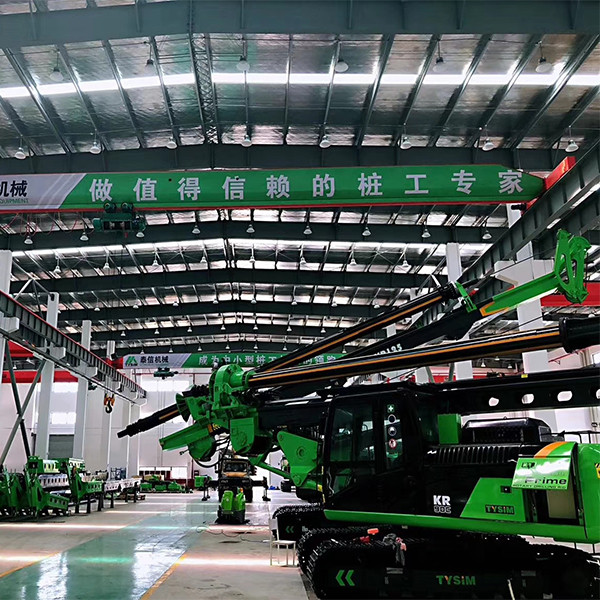

Case

Tysim developed the CAT chassis of the small rotary drill rig, the chassis with CAT global co-production services, the whole machine higher reliability won the praise of the customer. At present, our products have been sold to Australia, Russia, the United States, Argentina, Qatar, Turkey, southeast Asian countries and nearly 20 countries on every continent, representing Chinese manufacturing in the field of small and medium-sized rotary drilling rigs. Tysim led Luying association to successfully co-organize the ninth deep foundation engineering development forum and the first basic equipment fair, which made more domestic counterparts to understand the development achievements of Tysim machinery. Tysim sent KR90C rotary drilling rig to attend the 2019 BMW Germany exhibition. The focus and efforts of Tysim machinery will eventually be recognized by the market.