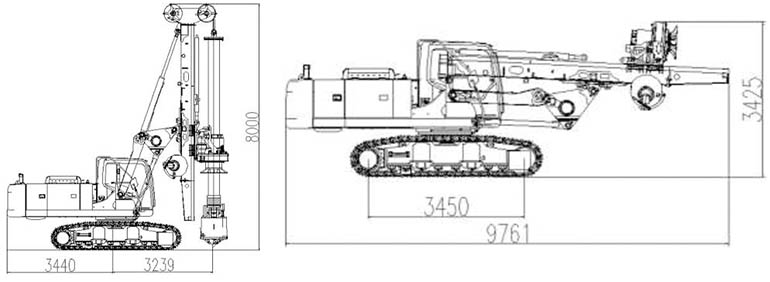

KR125ES Low headroom fully hydraulic rotary drilling rig

Video

Performance Characteristics

● The original made in USA powerful Cummins engine is selected to integrate with the core technology of TYSIM in electronic control system and hydraulic system to maximize its working performance.

● The whole series of Tysim products have passed GB certification and EU EN16228 standard certification, better dynamic and static stability design to ensure construction safety.

● TYSIM makes its own chassis specially for rotary drilling rig to perfectly integrate the power system with the hydraulic system. It adopts the most advanced load sensing; load sensitivity; and proportional control hydraulic system in China, making the hydraulic system to be more efficient and energy-saving.

● Perfectly matching the increased pressure with the power head torque for better efficiency when drilling rock.

● The power head is designed with an extra option for drilling rock to reduce the operation intensity of the operator, and greatly enhance the ability for drilling rock.

● Driven by double rotary motors to attain powerful rotary braking performance and to ensure stability and safety when drilling at extreme drilling torque.

● Front positioned single drive main winch with only two layers during operation to greatly improve the service life of the wire rope.

● The strong rotary braking performance provides stability and safety when drilling in extreme construction conditions so as to ensure the vertical degree of the pile.

● The height is only 8 meters in operational status, when matched with power head with big torque, it can meet most of the jobsite conditions with low clearance construction requirements.

Technical Specification

| Performance parameter | Unit | Numerical value |

| Max. torque | kN. m | 125 |

| Max. drilling diameter | mm | 1800 |

| Max. drilling depth | m | 20/30 |

| Working speed | rpm | 8~30 |

| Max. cylinder pressure | kN | 100 |

| Main winch pull force | kN | 110 |

| Main winch speed | m/mi n | 80 |

| Auxiliary winch pull force | kN | 60 |

| Auxiliary winch speed | m/mi n | 60 |

| Max. cylinder stroke | mm | 2000 |

| Mast side raking | ±3 | |

| Mast raking forward | 3 | |

| Angle of the mast forward | 89 | |

| System pressure | Mpa | 34. 3 |

| Pilot pressure | Mpa | 3.9 |

| Max. pull force | KN | 220 |

| Travel speed | km/h | 3 |

| Complete machine | ||

| Operating width | mm | 8000 |

| Operating height | mm | 3600 |

| Transport width | mm | 3425 |

| Transport height | mm | 3000 |

| Transport length | mm | 9761 |

| Total weight | t | 32 |

| Engine | ||

| Engine type | QSB7 | |

| Engine form | Six cylinder line, water cooled | |

|

turbocharged, air - to - air cooled |

||

| Cylinder number*cylinder diameter * stroke | mm | 6X107X124 |

| Displacement | L | 6. 7 |

| Rated power | kw/rpm | 124/2050 |

| Max.torque | N. m/rpm | 658/1500 |

| Emission standard | U. S. EPA | TIER 3 |

| Chassis | ||

| Track width (minimum *maximum) | mm | 3000 |

| Width of track plate | mm | 800 |

| Tail radius of rotation | mm | 3440 |

| Kelly bar | ||

| Model | Interlocking | |

| Outer diameter | mm | Φ377 |

| Layers * length of each section | m | 5X5. 15 |

| Max.depth | m | 20 |