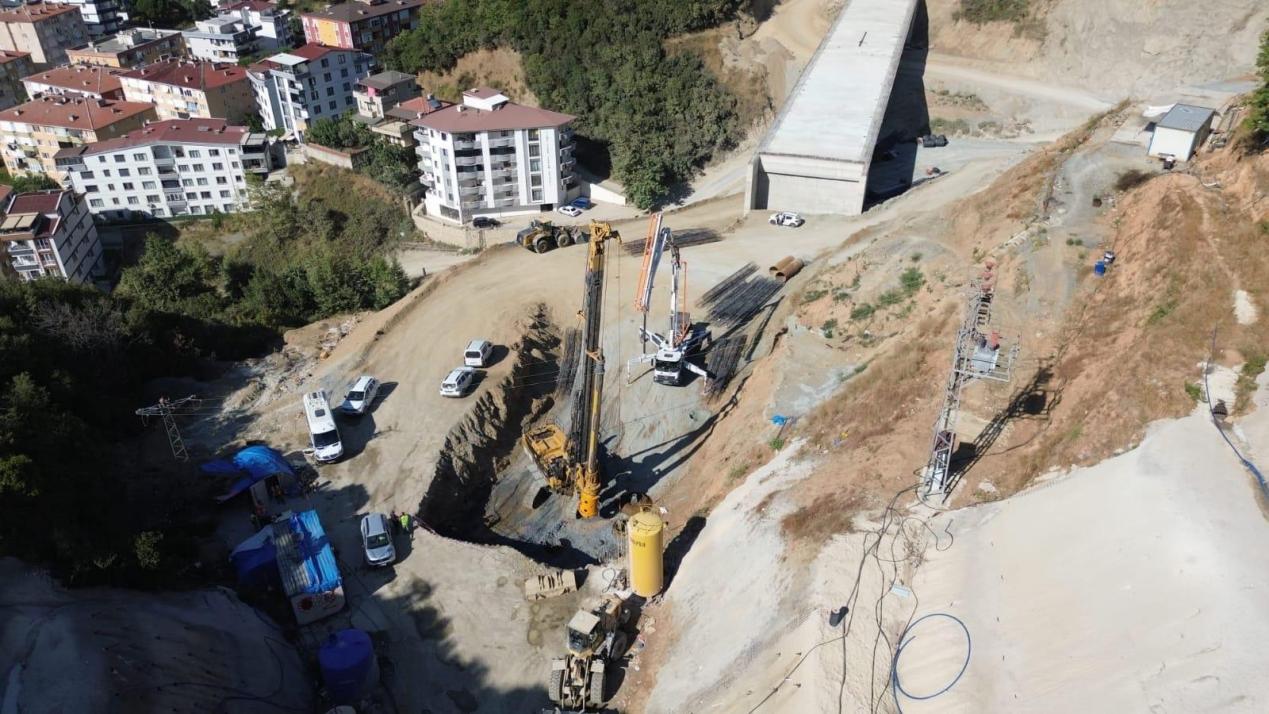

Recently, the bridge and tunnel project in Yalova Province, Turkey, has officially started. The KR360M rotary drilling rig with Caterpillar chassis, independently developed by TYSIM Piling Equipment Co., Ltd. (hereinafter referred to as "TYSIM"), has become the core construction equipment for this project. Yalova Province is located on the eastern coast of the Sea of Marmara in northwestern Turkey. It is a key transportation hub connecting major cities such as Istanbul and Bursa. After the completion of this bridge and tunnel project, it will further improve the local transportation network and promote regional economic development. This is also another important infrastructure construction project that TYSIM has participated in Turkey, following the Ankara-Istanbul High-Speed Railway Project.

.jpg)

Professional Equipment Solves Mixed Foundation Construction Challenges

The construction area of the Yalova Project has a typical mixed foundation and complex geological conditions. A large amount of water gushing occurs during some drilling processes, posing a severe test for construction equipment. TYSIM KR360M rotary drilling rig accurately copes with the complex stratum, relying on the excellent stability of the Caterpillar chassis and the independently developed intelligent hydraulic system. To address the water gushing issue, the equipment uses the modular designed steel casing wall protection technology, combined with the improved slag-cleaning drill bit. This effectively prevents hole wall collapse and ensures the safe progress of construction. Compared with traditional equipment, its construction efficiency has increased by nearly 30%, perfectly meeting the needs of Turkey's complex geological environment.

.jpg)

Precise Operation Enables Stable Pile Formation in 17m Deep Holes

In the Yalova Project, the KR360M drilling rig mainly undertakes pile foundation construction tasks. It uses 120cm-long conduits for concrete pouring operations, with a single pipe length of 5 meters and a required drilling depth of 17 meters. The advanced electronic control system equipped on the rig enables precise control of the drilling process, and it can still maintain a stable drilling rhythm even under water gushing conditions. Through the "slow pressing and light drilling" operation strategy, combined with underwater concrete pouring technology, the construction team ensures the pile formation quality of each pile foundation, laying a solid foundation for the subsequent construction of the main structure of the bridge and tunnel.

Technology Export Highlights Belt and Road Cooperation Vitality

The implementation of the Yalova Bridge and Tunnel Project not only improves the local transportation network, but also serves as another testament to the overseas expansion of China's high-end equipment manufacturing technology. The KR360M drilling rig is equipped with a high-power power system that meets Euro 5 emission standards, allowing it to adapt to the high-temperature environment in Turkey's summer. Its modular design also greatly reduces the difficulty of road transportation in mountainous areas. Through multiple prior technical communications and localized service responses, TYSIM has established deep trust in the Turkish market. This project will further consolidate its position in the Central and Eastern European infrastructure market and contribute Chinese wisdom to the infrastructure construction of countries along the Belt and Road Initiative.

Post time: Sep-02-2025